Scaffold tags play a vital role in ensuring safety on construction sites by visually communicating the condition of scaffolding structures. These tags provide workers and supervisors with critical information about whether a scaffold is safe to use, requires modifications, or is dangerous and should not be accessed.

With workplace safety being a top priority, scaffold tagging systems help prevent accidents, enhance efficiency, and ensure compliance with occupational safety regulations. This article explores scaffold tags, their importance, types, and regulatory requirements, providing a comprehensive guide for construction professionals.

What Are Scaffold Tags?

A scaffold tag is a physical or digital label attached to scaffolding structures to indicate their safety status. These tags are prominently placed at access points, making it easy for workers to identify if a scaffold is safe to use.

Purpose of Scaffold Tags

- Enhance Safety: Provide clear information on scaffold integrity, preventing accidents.

- Regulatory Compliance: Help construction companies meet the Occupational Safety and Health Administration (OSHA) and other industry safety regulations.

- Improve Communication: Allow instant, non-verbal communication between workers, inspectors, and supervisors.

- Reduce Downtime: Ensure scaffolding is inspected and safe before work begins, minimizing delays.

Types of Scaffold Tags

Scaffold tags play a crucial role in construction site safety by indicating whether a scaffold is safe for use, requires caution, or is unsafe. These tags are colour-coded for quick identification and ensure compliance with safety standards. Below are the different types of scaffold tags used in the industry, their meanings, and when they should be used.

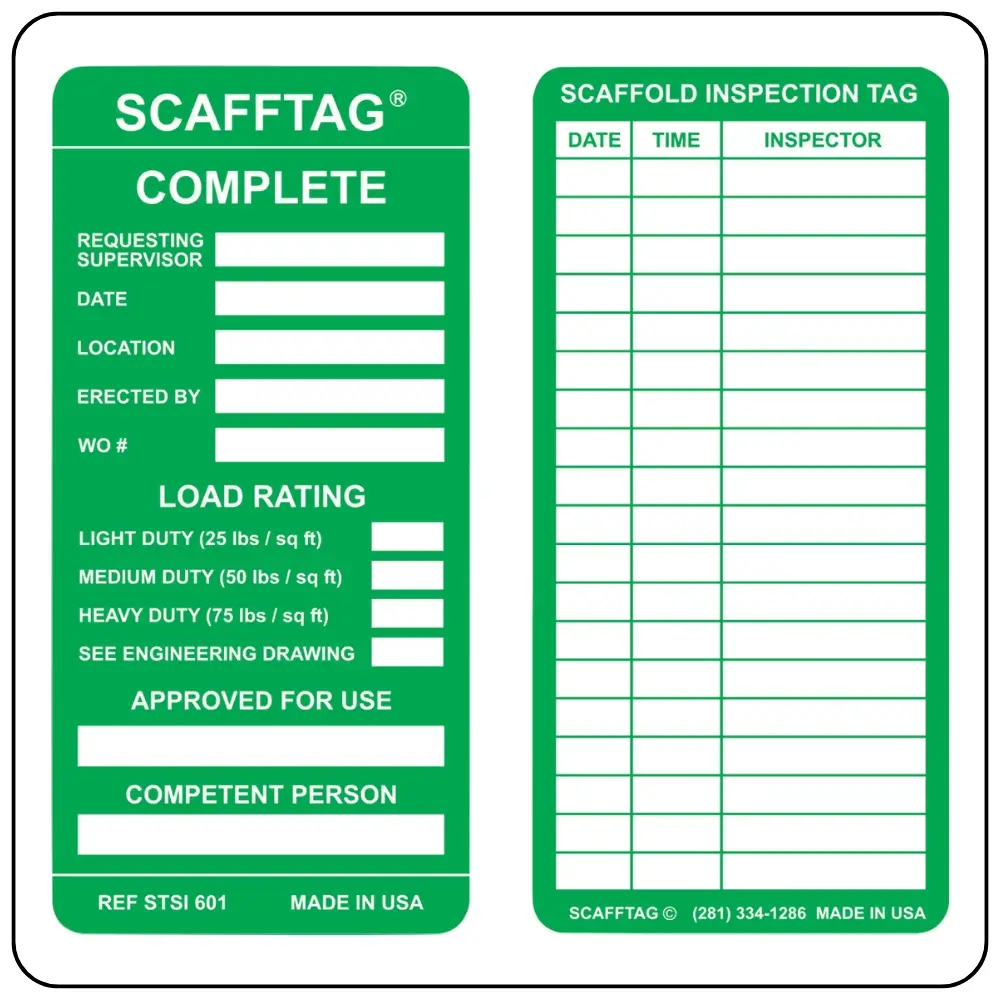

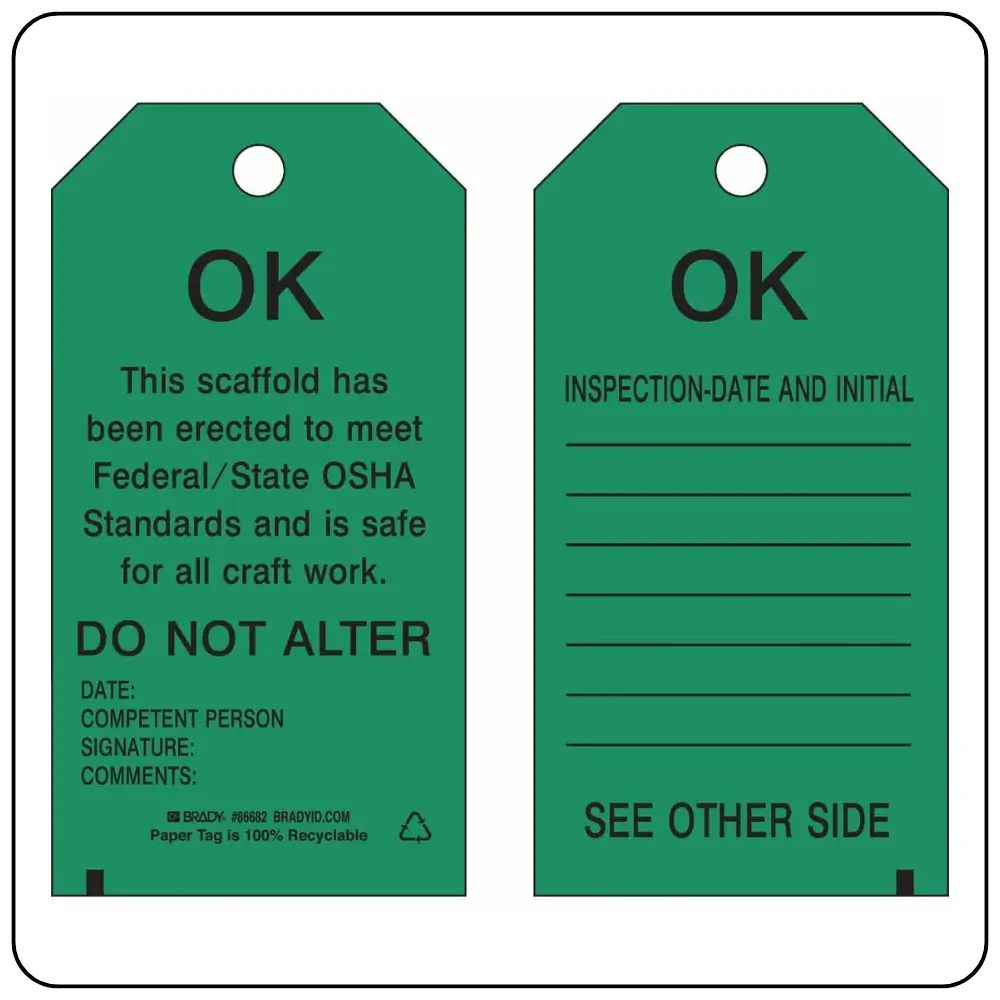

1. Green Scaffold Tags – “Safe for Use”

Green scaffold tags indicate that a scaffold has been inspected and deemed safe for use. These tags signify that the structure meets all required safety regulations and standards, and workers can use it without additional precautions beyond normal safety protocols.

When to Use

- After a thorough inspection, it confirms that the scaffold is structurally sound.

- When the scaffold is properly assembled following the manufacturer’s specifications.

- When there are no identified hazards, modifications, or structural issues.

Information Included on the Tag

- Date of the last inspection.

- Name and signature of the inspector.

- Load capacity and any relevant weight restrictions.

- Notes regarding any safety measures or requirements.

Best Practices for Usage

- Attach the green tag at all scaffold access points.

- Ensure it is weather-resistant to remain visible.

- Regular re-inspections should be conducted to maintain green tag status.

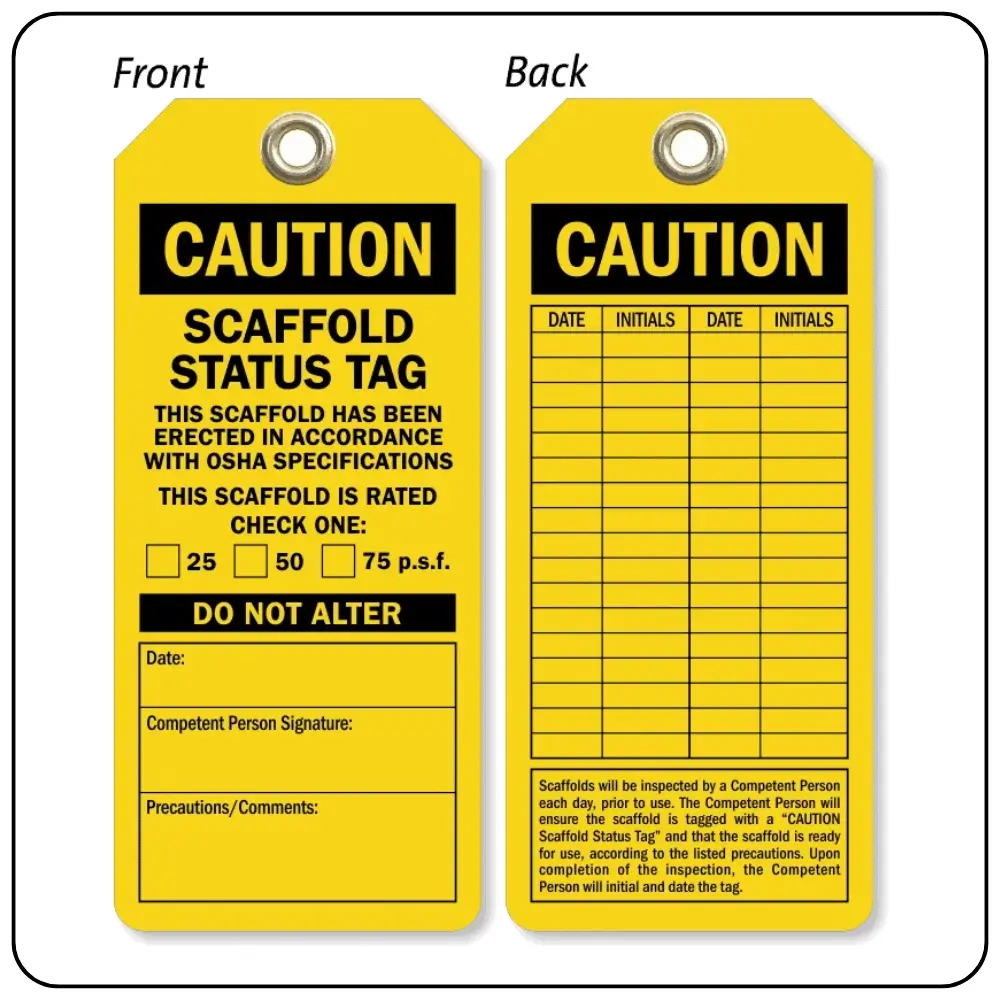

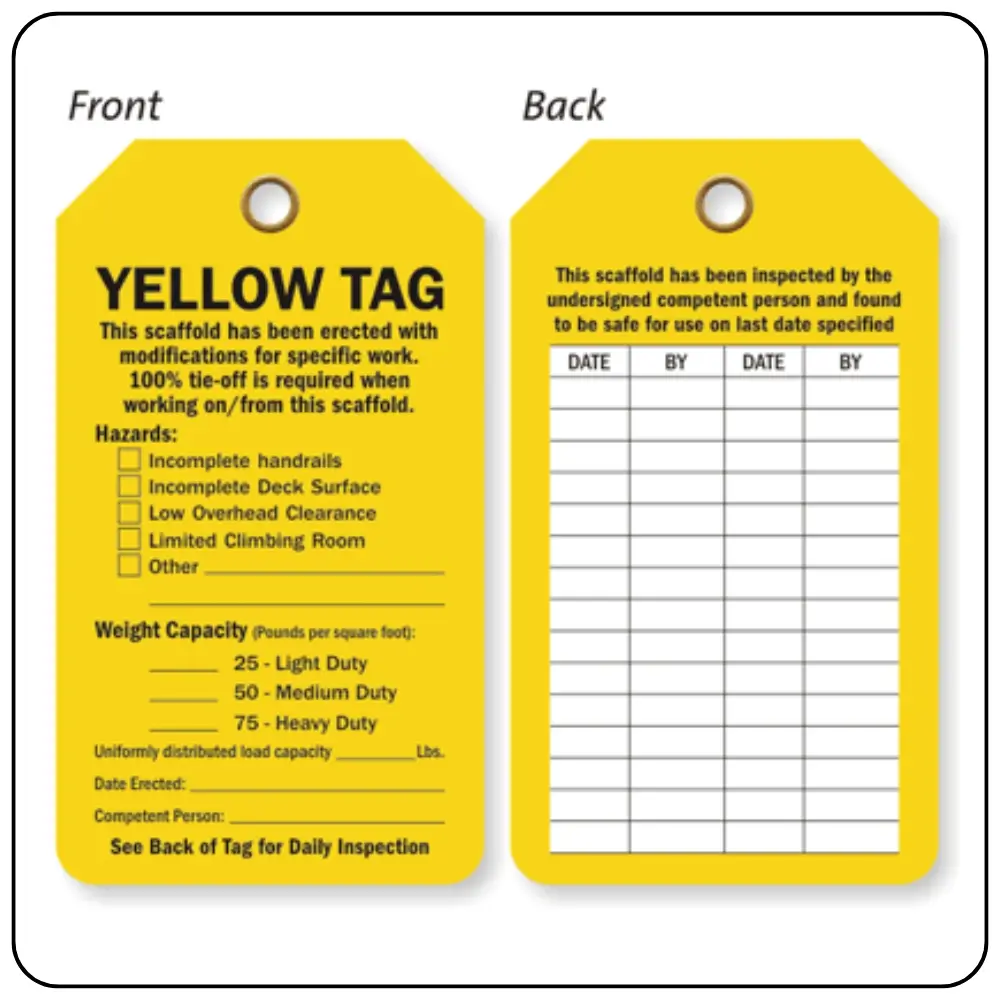

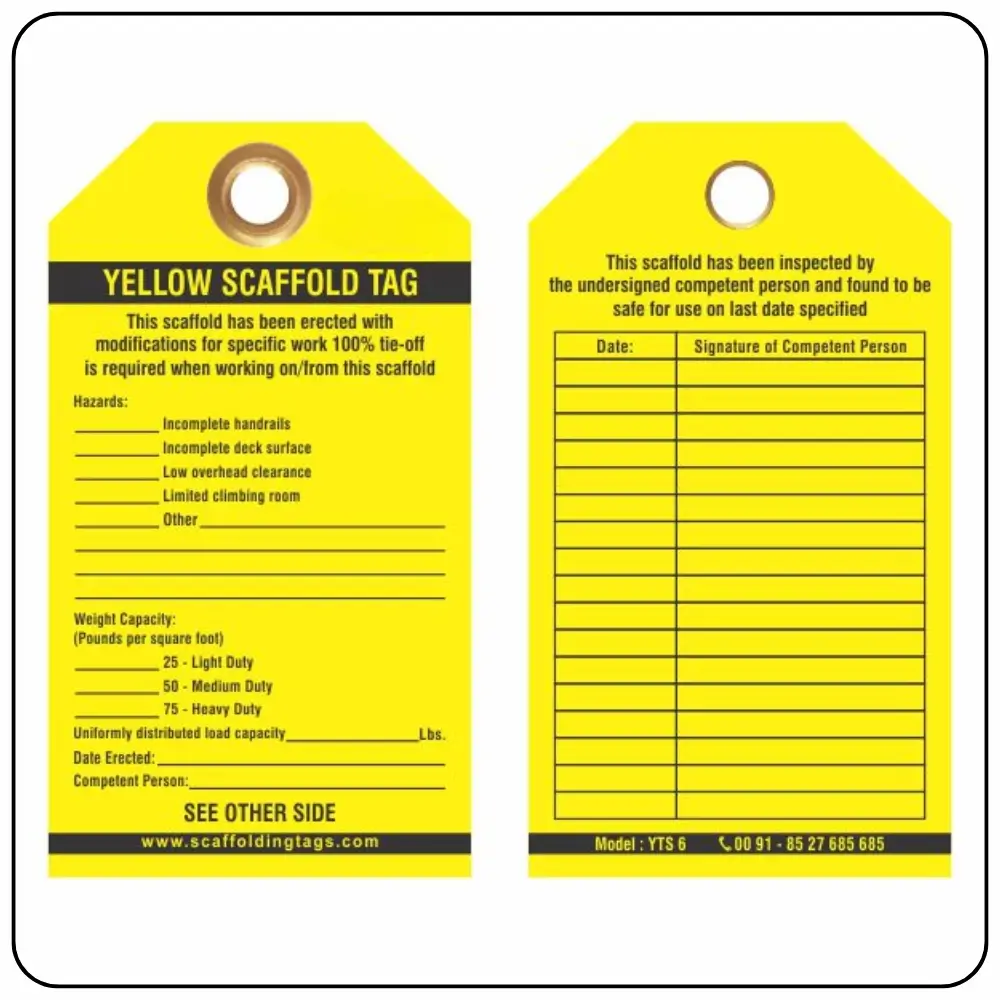

2. Yellow Scaffold Tags – “Caution”

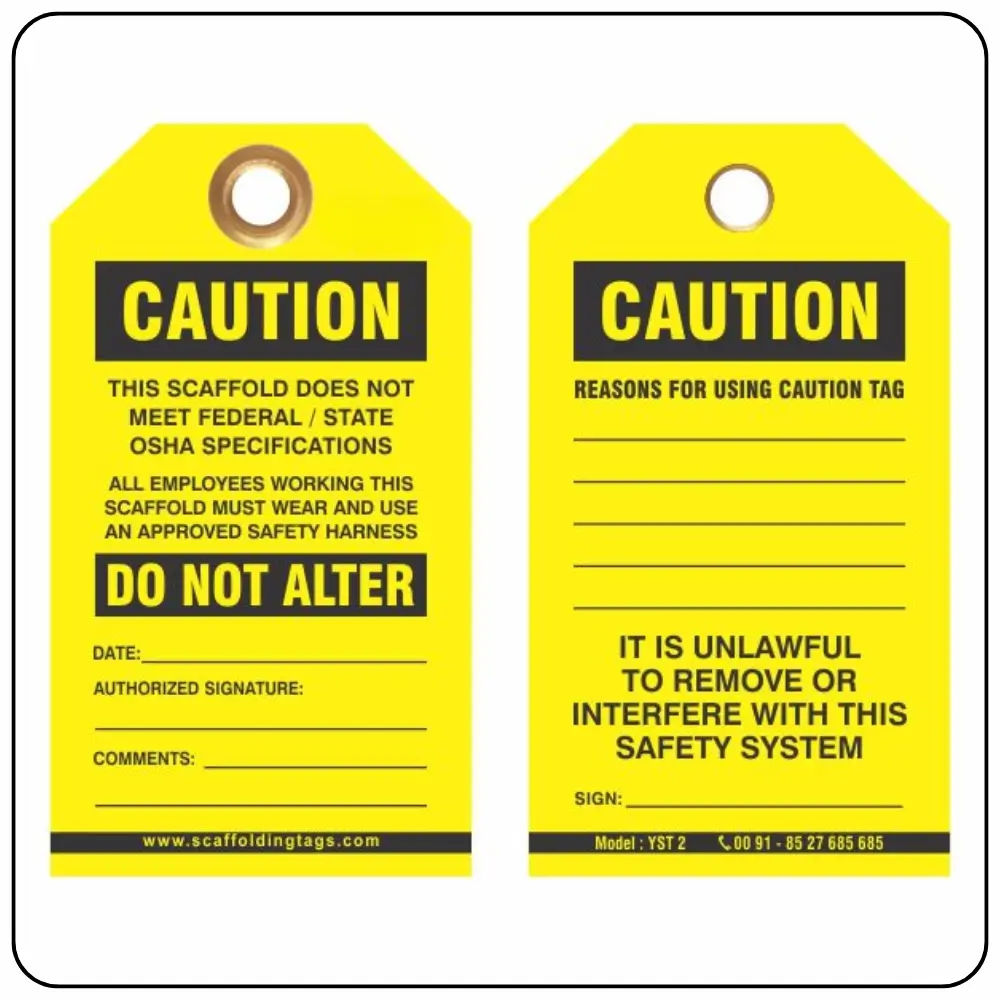

Yellow scaffold tags indicate that the scaffold is safe to use but has some limitations or potential hazards. These tags warn that certain precautions must be taken before use. A scaffold with a yellow tag may have modifications that introduce risks or require additional protective measures.

When to Use

- When the scaffold has been altered from its original design to meet specific work requirements.

- When minor safety concerns or defects have been noted but do not render the scaffold completely unsafe.

- When the scaffold requires using personal protective equipment (PPE), such as fall arrest systems or harnesses.

- When environmental conditions, such as high winds, pose a potential safety risk.

Information Included on the Tag

- Identified hazards or modifications.

- Special precautions or required safety measures.

- Name and signature of the inspector.

- Date of inspection and recommended date for re-inspection.

Best Practices for Usage

- Workers should read and understand the safety concerns listed before using the scaffold.

- The scaffold should be re-evaluated regularly to determine if the tag needs to be changed to green or red.

- Additional safety barriers or warnings should be used if the risk is significant.

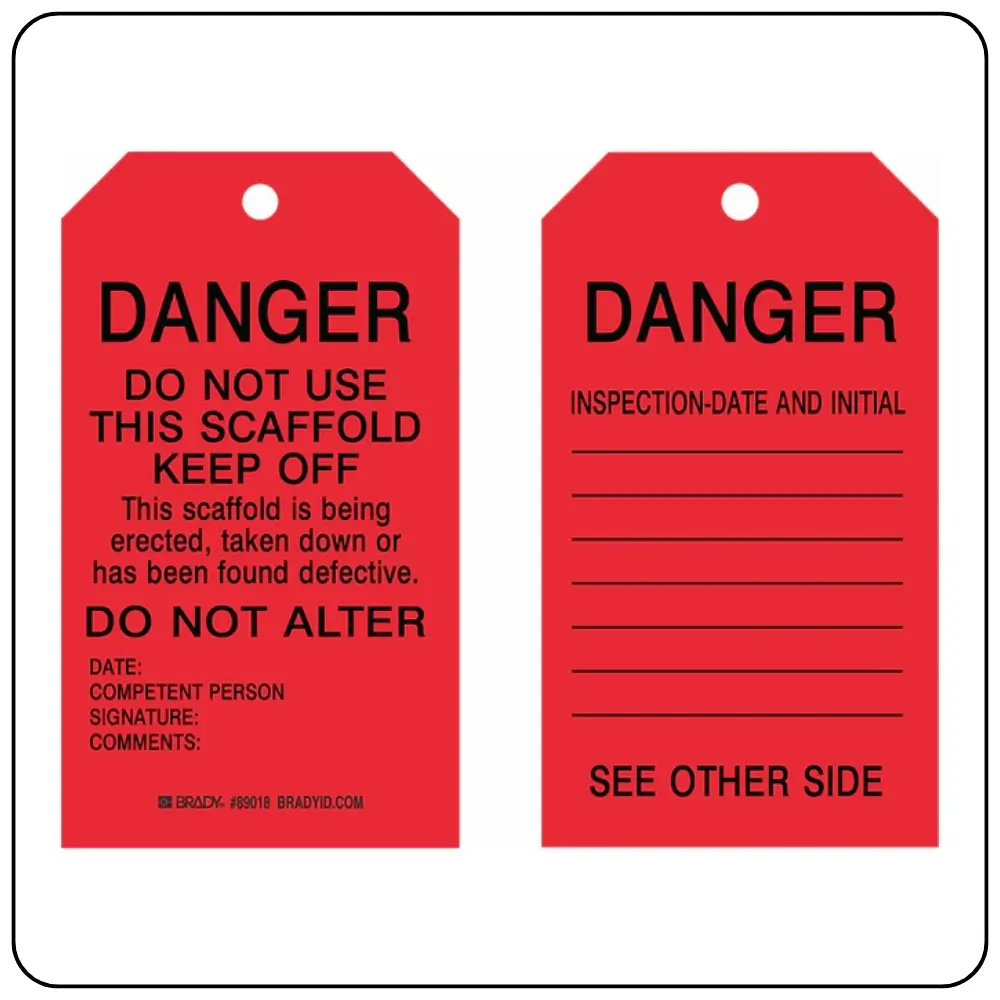

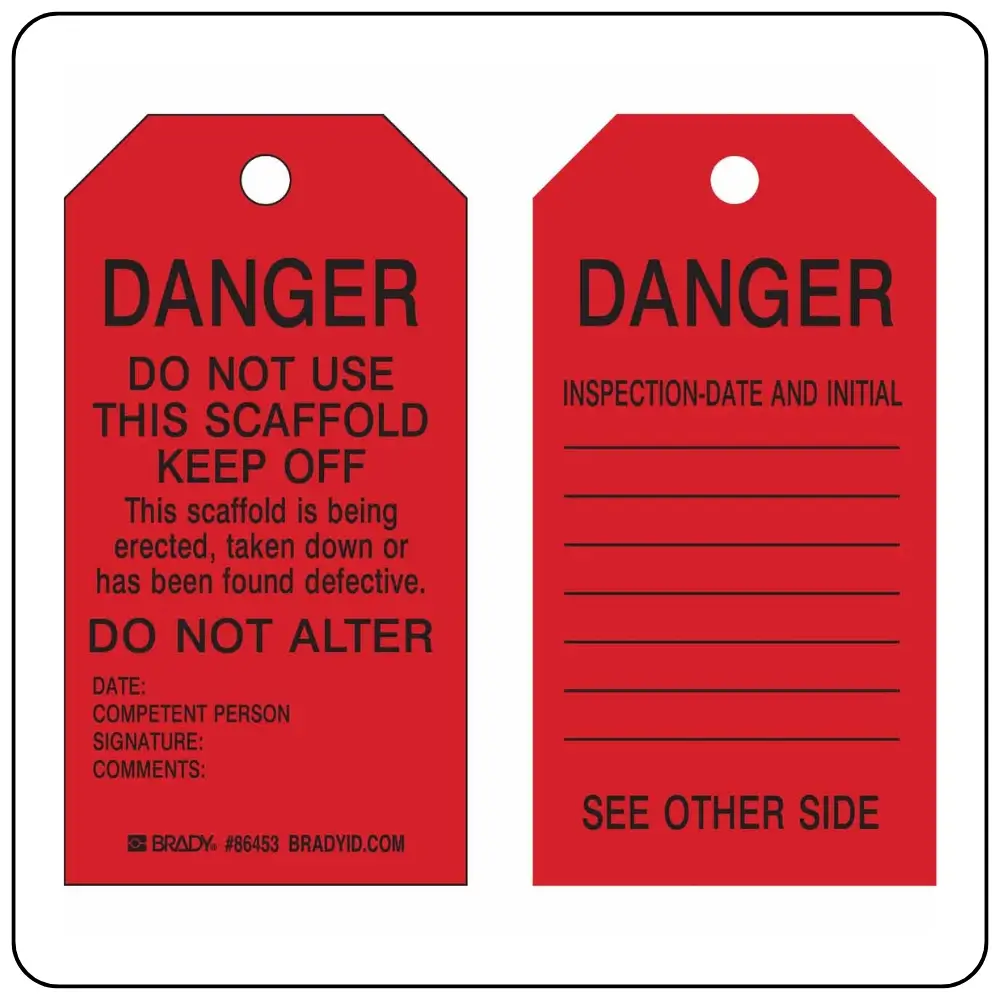

3. Red Scaffold Tags – “Do Not Use”

Red scaffold tags indicate that the scaffold is unsafe for use. This could be due to structural defects, incomplete assembly, or other significant safety hazards. These tags serve as a strict warning that workers should not climb or use the scaffold under any circumstances.

When to Use

- When the scaffold is under construction or being dismantled.

- When significant structural issues have been identified, such as broken components, missing guardrails, or unstable footing.

- When an inspection has deemed the scaffold unsafe for use until repairs or modifications are made.

- When extreme weather conditions have compromised the scaffold’s integrity.

Information Included on the Tag

- The reason why the scaffold is unsafe.

- Required repairs or modifications before re-inspection.

- Name and signature of the inspector.

- Date of inspection and estimated date for resolution.

Best Practices for Usage

- Place the red tag at all scaffold entry points to prevent unauthorized access.

- Remove all access ladders or barriers if possible to prevent accidental use.

- The scaffold should not be used until a competent person re-inspects it and approves it for use by replacing the red tag with a green tag.

4. Blue Scaffold Tags – “Additional Information” (Optional)

While not universally used, blue scaffold tags provide additional information about the scaffold, such as load capacity, maintenance history, or site-specific instructions. These tags do not replace the standard green, yellow, or red tags but serve as a supplement.

When to Use

- To provide extra details about the scaffold’s structural integrity.

- To document maintenance and repair records.

- To indicate specific load-bearing limits that must be followed.

Information Included on the Tag

- Weight capacity limits.

- Maintenance and service history.

- Notes from previous inspections that do not necessarily affect safety but should be recorded.

Best Practices for Usage

- Should be used in conjunction with a green, yellow, or red tag.

- Placed in a visible location near scaffold access points.

- Used for record-keeping and reference rather than immediate safety communication.

Scaffold tags are an essential part of construction site safety, providing clear visual indicators of the structural integrity and usability of scaffolds. The green tag signifies that the scaffold is safe for use, the yellow tag indicates caution due to modifications or potential risks, and the red tag warns that the scaffold is unsafe and should not be used. Some sites also use blue tags to provide additional non-safety-related information.

Scaffold Tagging Requirements

Scaffold tagging is an essential safety practice in construction and industrial worksites. It ensures that scaffolding structures are properly inspected and categorized based on their safety status. By following a structured scaffold tagging system, companies can prevent accidents, comply with legal requirements, and enhance overall worksite efficiency.

Let’s discuss the key scaffold tagging requirements, covering regulatory compliance, necessary information on tags, placement, inspection frequency, and best practices to maintain a safe working environment.

1. Regulatory Compliance and Industry Standards

While scaffold tags themselves are not always legally required, safety regulations mandate that scaffolding must be regularly inspected and any safety concerns must be clearly communicated to workers. Below are key regulations governing scaffold tagging requirements:

OSHA (United States) – 29 CFR 1926.451 and 29 CFR 1926.200(h)(1)

- OSHA requires scaffolds to be inspected before first use, at least once every shift, and after any event that could affect their stability (e.g., storms, modifications, or heavy loads).

- Although OSHA does not explicitly mandate scaffold tags, 29 CFR 1926.200(h)(1) requires warning signs or tags on defective or hazardous equipment, making scaffold tagging a recommended safety practice.

Health and Safety Executive (HSE – United Kingdom)

- The Work at Height Regulations 2005 mandates that scaffolds over 2 meters in height must be inspected before first use, weekly thereafter, and after any alterations or adverse weather conditions.

- While tags are not legally required, HSE recommends using scaffold tags as a best practice for improving safety communication.

Safe Work Australia

- Australian scaffold safety standards require scaffolds over 4 meters high to be inspected before use and at least every 30 days.

- The use of color-coded scaffold tags is encouraged to clearly mark the scaffold’s status and compliance.

Other International Standards

- Many other countries follow similar regulations based on ISO 9001 and ISO 45001 safety management systems.

- Construction companies often adopt best practices from OSHA, HSE, and Safe Work Australia to maintain a safe and legally compliant work environment.

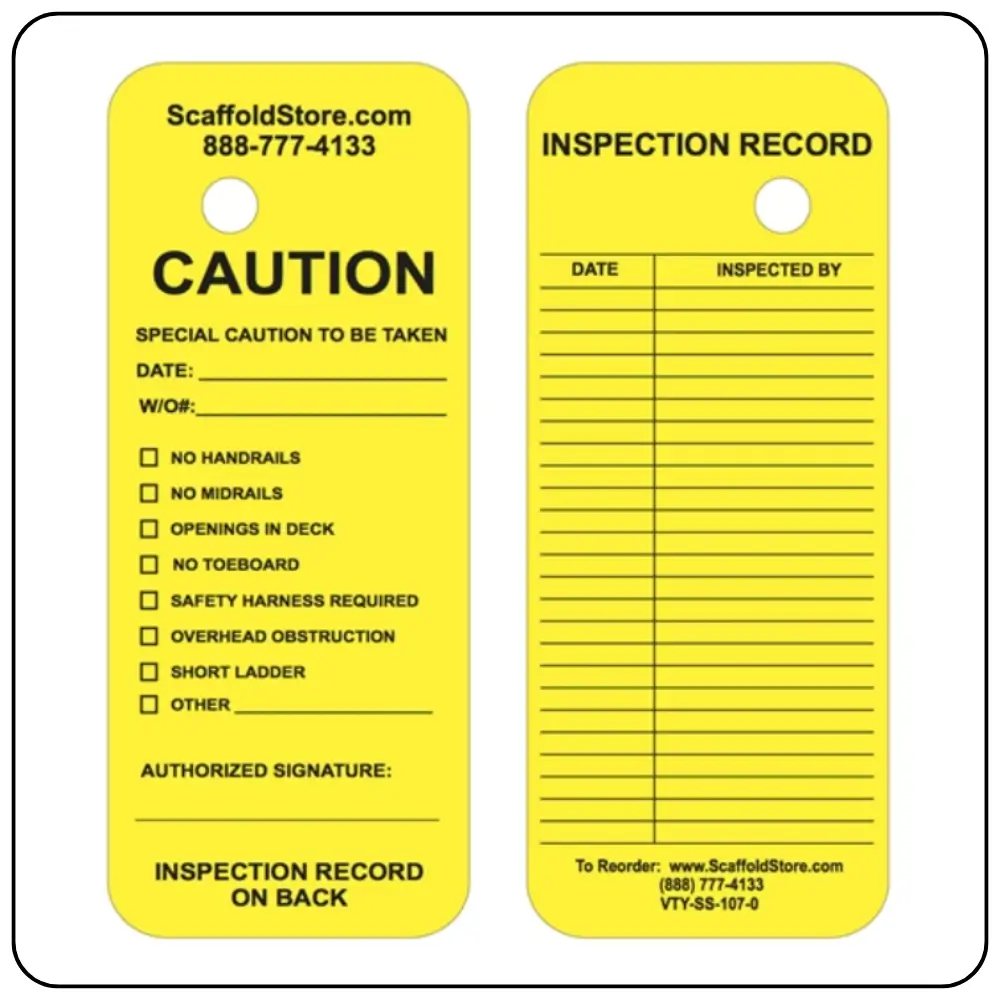

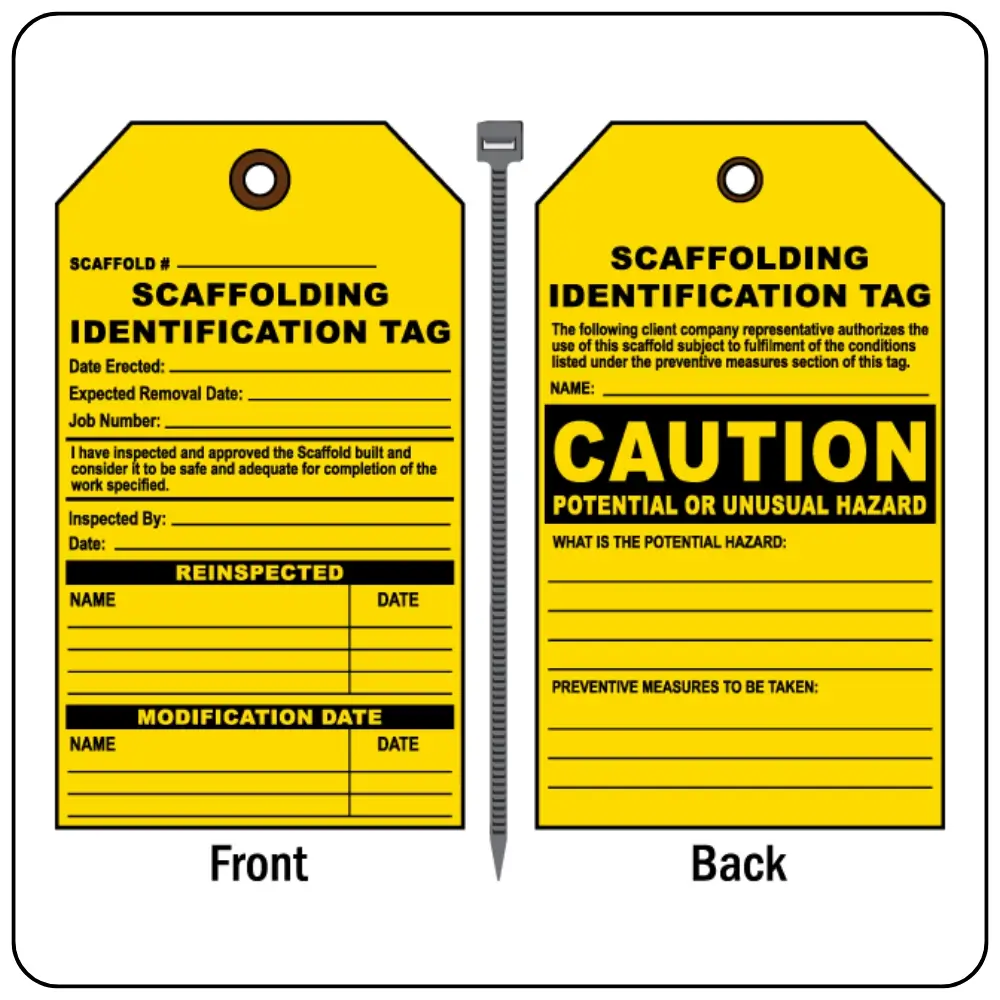

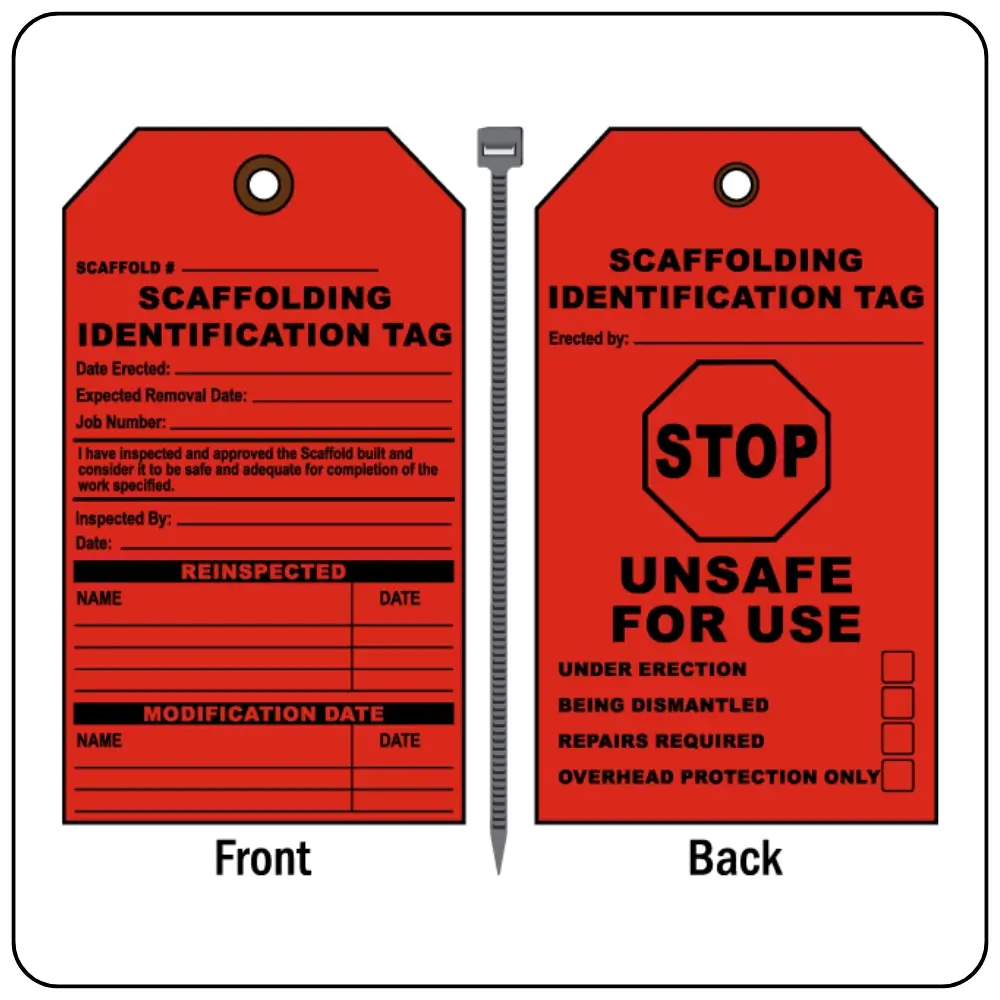

2. Required Information on Scaffold Tags

Each scaffold tag must contain specific details to ensure proper documentation and clear communication. Regardless of the color (green, yellow, or red), all scaffold tags should include the following information:

Essential Details on a Scaffold Tag

- Scaffold Identification Number – A unique ID for tracking inspections and repairs.

- Inspection Date – The most recent inspection date and the next due inspection.

- Inspector’s Name and Signature – The competent person responsible for the inspection.

- Load Capacity – The maximum weight the scaffold can safely support.

- Scaffold Status – Whether the scaffold is safe (green), requires caution (yellow), or is unsafe (red).

- Modifications or Hazards – If applicable, notes on required PPE, structural adjustments, or worksite-specific risks.

Based on site requirements, such as weather conditions, project number, or specific safety warnings, additional details may be included.

3. Proper Placement of Scaffold Tags

Scaffold tags must be clearly visible to all workers to ensure that safety information is accessible before using the scaffold.

Best Practices for Scaffold Tag Placement

- At all access points – Tags should be affixed near ladders, stair towers, and entryways.

- At eye level – Workers should easily spot and read the tag before entering the scaffold.

- Weather-protected – Laminated tags or plastic holders should be used to prevent fading or damage.

- On each scaffold level (if necessary) – Placing tags on different levels for multi-tier scaffolding can help workers identify risks at each stage.

4. Inspection Frequency and Re-Tagging Requirements

Regular inspections are critical for scaffold safety. The frequency of scaffold inspections depends on regulatory standards, worksite conditions, and scaffold modifications.

Scaffold Inspection and Re-Tagging Schedule

- Before First Use – A competent person must inspect and tag the scaffold before workers use it.

- Daily (for high-risk sites) – Frequent inspections may be necessary if the scaffold is in a hazardous environment.

- Weekly (as per HSE regulations) – In many countries, scaffolds must be inspected at least once weekly.

- After Modifications – If any changes are made to the scaffold, a new inspection and updated tag are required.

- After Extreme Weather – Heavy rain, snow, or strong winds can weaken scaffolding, requiring immediate re-inspection and potential re-tagging.

- After an Incident or Structural Impact – If a scaffold has been struck by heavy machinery or damaged by falling objects, it must be inspected before reuse.

If a scaffold fails inspection, the green tag should be replaced with a yellow or red tag, and the necessary repairs should be made before re-inspection.

5. Best Practices for an Effective Scaffold Tagging System

Companies should implement standardised scaffold tagging procedures to maintain a safe and organized worksite. Below are best practices for improving scaffold safety compliance:

Training and Competency

- Only a competent person (as defined by OSHA and HSE) should conduct scaffold inspections and tagging.

- Workers should be trained to read scaffold tags and understand their significance.

- Supervisors should enforce strict policies regarding the use of tagged scaffolds.

Record Keeping and Digital Tagging

- Maintain detailed logs of scaffold inspections, including photos and digital records.

- Consider using QR code-enabled digital scaffold tags for instant access to inspection histories.

- Keep inspection reports accessible on-site for quick reference during safety audits.

Consistent Re-Evaluation

- Review scaffold tagging policies periodically to ensure compliance with updated regulations.

- Conduct random safety audits to verify scaffold tags are correctly placed and updated.

- Assign dedicated safety personnel to oversee scaffold inspections and tagging enforcement.

Scaffold tagging is a fundamental component of construction site safety. By following regulatory requirements, ensuring proper placement, maintaining inspection schedules, and implementing best practices, companies can prevent workplace accidents, comply with safety standards, and create a more efficient work environment.

Benefits of Using Scaffold Tags

Scaffold tags are critical in maintaining workplace safety, ensuring compliance with regulations, and improving overall work efficiency on construction sites. By clearly indicating the safety status of scaffolding structures, these tags help to prevent accidents, streamline communication, and enhance operational productivity. Below are the key benefits of using scaffold tags in industrial and construction environments.

1. Enhanced Worker Safety and Accident Prevention

Scaffold tags serve as a visual safety indicator, allowing workers to quickly assess whether a scaffold is safe to use. By following a color-coded system (green, yellow, red), workers can immediately determine the structure’s safety status, reducing the risk of falls, structural collapses, and other accidents.

How It Prevents Accidents:

- Clearly marks unsafe scaffolding with red tags to prevent use.

- Identifies potential hazards with yellow tags, prompting extra precautions.

- Confirms safe scaffolding with green tags, reducing uncertainty for workers.

Without scaffold tags, workers might unknowingly use unstable or uninspected scaffolding, increasing the chances of serious workplace injuries.

2. Regulatory Compliance and Legal Protection

Construction companies must adhere to safety regulations established by organizations such as:

- Occupational Safety and Health Administration (OSHA) – United States

- Health and Safety Executive (HSE) – United Kingdom

- Safe Work Australia

- International Organization for Standardization (ISO)

While scaffold tags themselves may not be legally required in every country, regular scaffold inspections are mandatory. Using scaffold tags provides a clear and documented system to show that inspections have been performed, helping companies stay compliant and avoid legal penalties.

Regulatory Compliance Benefits:

- Demonstrates adherence to safety laws and industry standards.

- Provides documented proof of scaffold inspections, protecting companies from liability.

- Prevents worksite shutdowns or fines due to non-compliance.

If an accident occurs and scaffolding inspections were not properly documented, companies could face lawsuits, fines, or even criminal charges.

3. Improved Communication Among Workers and Supervisors

Scaffold tags act as non-verbal communication tools, ensuring that all team members, including supervisors, inspectors, and workers, have instant access to the scaffold’s safety status. This reduces the need for verbal confirmations and eliminates misunderstandings that could lead to workplace hazards.

Communication Benefits:

- Tags are placed at entry points, ensuring all workers see them.

- Reduces confusion about scaffold usability.

- Prevents unauthorized access to unsafe or under-maintenance scaffolds.

For multilingual workforces, scaffold tags eliminate language barriers by using a universal color system that workers can easily recognize.

4. Increased Worksite Efficiency and Productivity

When scaffold tags are used effectively, workers can quickly identify which scaffolds are ready for use and avoid delays caused by inspecting or questioning scaffold safety. This allows teams to focus on their tasks without unnecessary interruptions.

Efficiency-Boosting Features:

- Reduces downtime – Workers don’t waste time checking whether scaffolds are safe.

- Speeds up inspections – Inspectors can easily track which scaffolds need attention.

- Prevents workflow disruptions – Unsafe scaffolds are clearly marked, so workers don’t unknowingly use them and cause delays due to accidents.

A well-tagged scaffold system ensures that construction projects stay on schedule, improving overall site efficiency and meeting project deadlines.

5. Clear Documentation and Accountability

Scaffold tags provide a record-keeping system that helps track inspections, repairs, and modifications. This documentation is valuable for audits, incident investigations, and maintenance planning.

Key Documentation Benefits:

- Tracks inspection history – Each tag includes the date of inspection, inspector’s name, and scaffold condition.

- Provides accountability – If issues arise, companies can review who last inspected the scaffold and when.

- Assists in audits and reporting – Helps companies stay compliant with safety regulations and avoid potential fines.

A digital scaffold tagging system (e.g., QR-code-enabled tags) can further streamline record-keeping and inspection tracking.

6. Risk Mitigation and Insurance Benefits

Scaffolding-related accidents can lead to costly worker compensation claims, insurance premium increases, and project delays. By implementing a proper scaffold tagging system, companies can reduce their risk exposure and potentially lower insurance costs.

Risk Management Benefits:

✔ Fewer workplace accidents mean lower insurance claims and reduced liability.

✔ Insurance companies may offer better rates to companies with strong safety practices.

✔ Minimizes financial losses caused by project delays due to scaffold-related incidents.

When scaffold safety is well-documented and enforced, companies have a strong defense against liability claims and lawsuits.

7. Simplifies Inspection and Maintenance Processes

Scaffold inspections must be conducted regularly, and scaffold tags make it easier to identify which structures require maintenance or repairs.

How It Helps Inspectors and Maintenance Teams:

✔ Identifies unsafe scaffolds immediately without requiring separate reports.

✔ Prioritizes repairs and maintenance for red-tagged scaffolds.

✔ Ensures scaffolds are checked regularly, reducing the chances of unexpected failures.

By following a structured tagging system, scaffolding-related maintenance is streamlined, ensuring faster repairs and a safer worksite.

8. Creates a Culture of Safety Awareness

Using scaffold tags reinforces a strong safety culture in workplaces by reminding workers to always check scaffold status before use. It also encourages employees to be proactive about safety by reporting missing or outdated tags.

Safety Culture Benefits:

- Ensures that safety procedures become routine for all workers.

- Encourages worker engagement by allowing them to report safety concerns.

- Increases overall site safety awareness, leading to fewer accidents.

A well-established scaffold tagging system clearly conveys that worker safety is a top priority.

Scaffold tags provide a simple but highly effective safety solution for construction and industrial worksites. They prevent accidents, improve compliance with safety regulations, and enhance worksite efficiency. By clearly marking scaffolding structures, these tags help workers quickly assess safety conditions, reducing confusion and delays.

FAQs About Scaffold Tags

Conclusion

Scaffold tags are crucial to worksite safety, ensuring that workers can quickly assess the usability of scaffolding structures. By implementing a proper tagging system, construction companies can enhance safety, streamline operations, and remain compliant with industry regulations.

- Always check scaffold tags before use.

- Follow safety guidelines and industry best practices.

- Prioritize regular inspections to maintain structural integrity.

Following these best practices ensures a safer, more efficient construction site for everyone. Stay safe, and tag your scaffolds correctly!